BRANDS THAT TRUST US

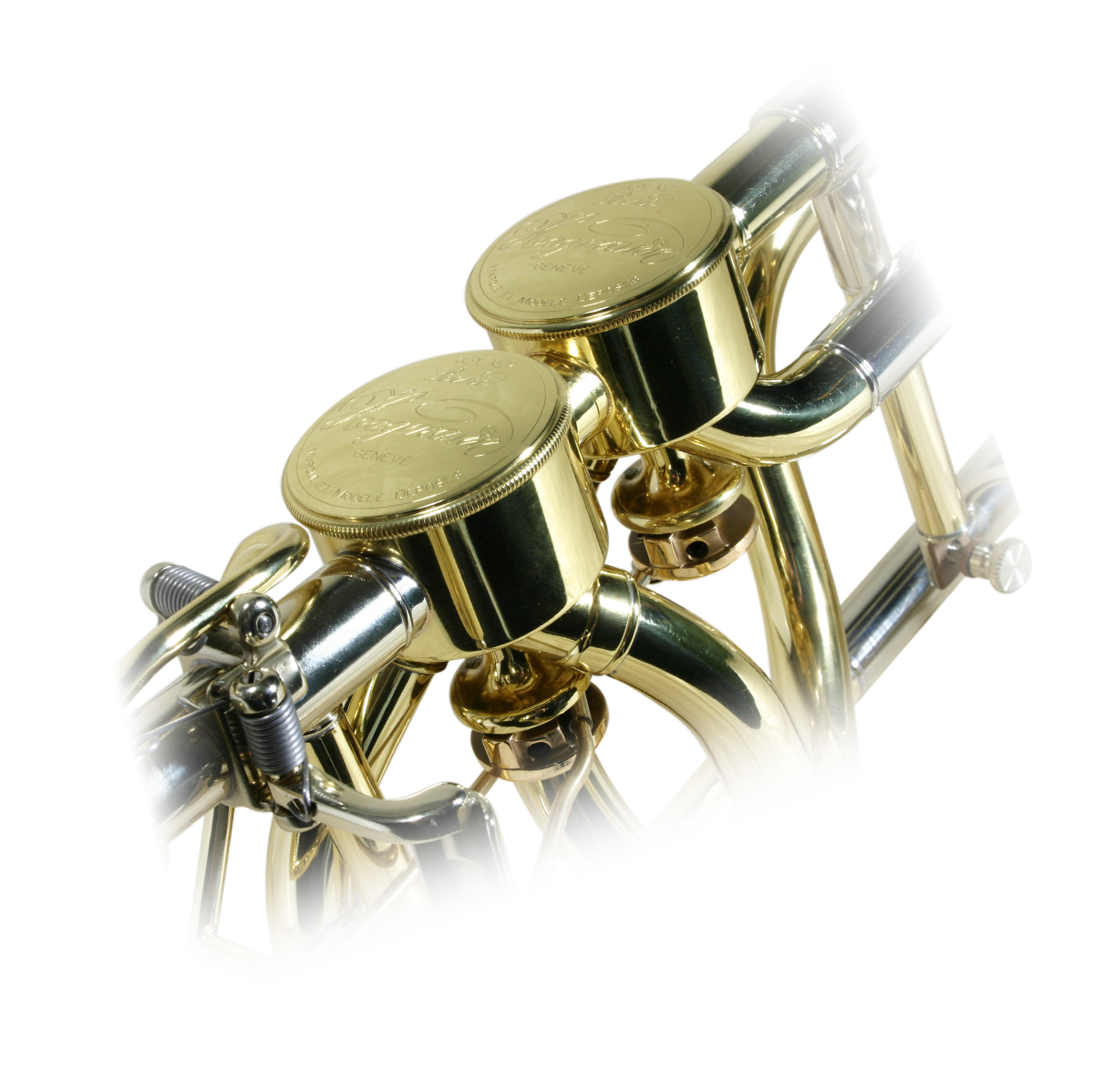

Valve design concept

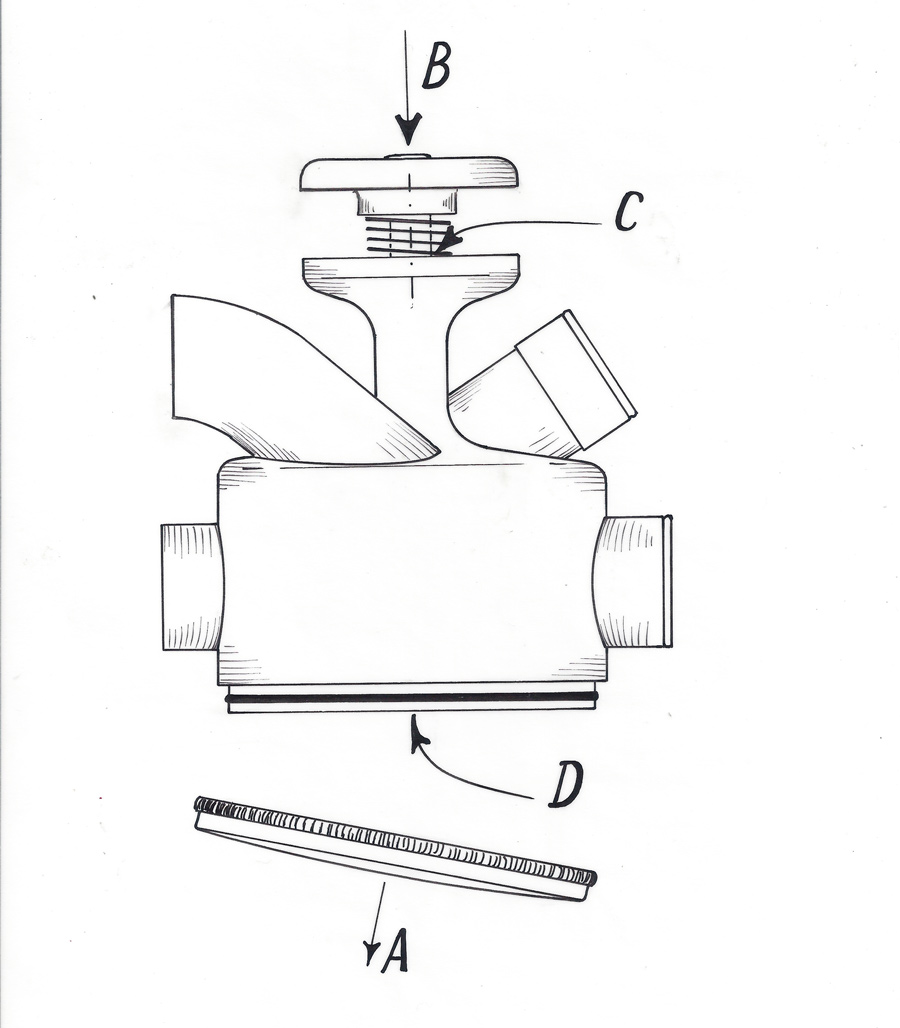

The 3-bypass valve is illustrated below:

The numerous angles and passage restrictions of traditional valves disrupt the air column. This results in irregular emission and tone with increased resistance. As the Hagmann valve has no restrictions on the air column, no angles and no excessively sharp bending radiuses of the internal ducts, the emission is full and easy, very homogeneous through all registers from pianissimo to fortissimo.

Since the 70s, there have been various attempts to improve the acoustics of the traditional valve. With his own, René Hagmann pays tribute to another enthusiast, Ed Thayer, a pioneer indeed, but one whose creation was perfectible in terms of maintenance, if only regarding the complex lubrication involved with his design.

The advantages in a nutshell are:

Fuller, purer sound

More centered and homogeneous in all registers

Greatly improved emission

Easier playing, less demanding and more open

Superior dynamics and better expression

Thanks to the René Hagmann valve, your future trombone will have the same emission and sound performance as an instrument without F and/or D attachments.

The Hagmann valves for trombone

Tenor trombone models

TTB36

13.5mm bore Bb duct, 13.5mm bore F duct.

TTB42.DB

13.5mm bore Bb duct, 14.0mm bore F duct.

TTB42.138

13.8 mm bore Bb duct,14.0mm bore F duct.

TTB42.140

14.0mm bore Bb duct, 14.0mm bore F duct.

TTB42.142

14.2mm bore Bb duct, 14.0mm bore F duct.

Bass trombone models

Single Bb/F valve

BTBF.150

15. mm bore, cylindrical ducts and knuckles.

BTBF.152

15.2mm bore, cylindrical ducts and knuckles.

PBBF

“Progressive bore“, 14.6mm to 15.0mm tapered Bb bore,15.0mm bore F wrap.

TSBF

“Two steps“, 14.8mm cylindrical Bb bore, 15.0mm bore F wrap.

Independent online valve sets

BTBF+BTBDc.150

Our “classic” set, 15.0mm general bore, one curved knuckle on the D wrap port.

BTBF+BTBDc.152

Our “classic” set, 15.2mm general bore, one curved knuckle on the D wrap port.

BTBF+BTBD.150

Our “classic” set, 15.0mm general bore but without curved knuckle, also suitable for dependent system.

BTBF+BTBD.152

Our “classic” set, 15.2mm general bore but without curved knuckle, also suitable for dependent system.

PBBF+PBBDc

“Progressive bore” set, tapered Bb 14.6 to 15.6mm bore. Dependent valves set-up.

TSBF+TSBDc

“Two-steps” set: F valve: 14.8mm Bb straight-through, 15.0mm F port. D valve: 15.2mm Bb straight-through, 15.0mm D duct. Curved knuckle on the D wrap port.

Proceed as follows:

Proceed as follows: